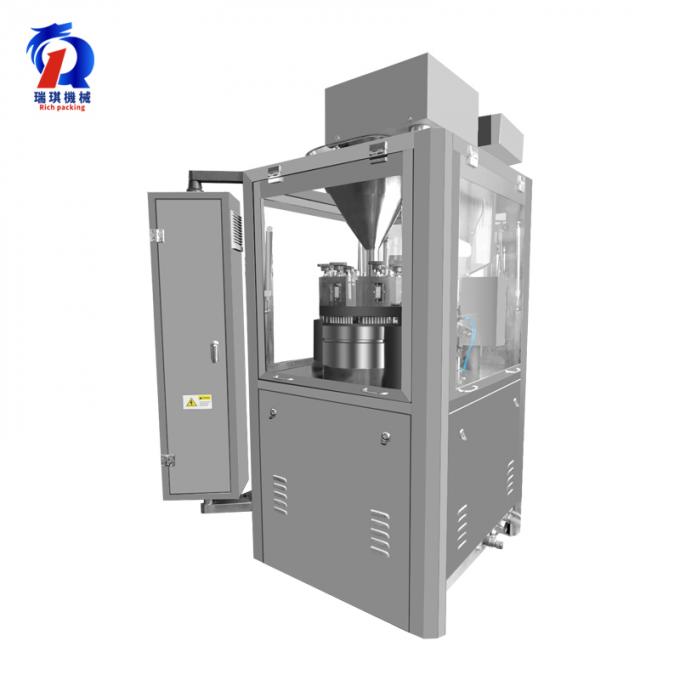

Pharmaceutical Capsule Filling Machine 900*870*1950mm Dimension

Detailed Product DescriptionName:NJP 1200 High Speed Automatic Capsule Filler Equipment Pharmacy MachinesAfter-sales Service Provided:Ingénieurs disponibles pour entretenir les machines à l’étranger,Support technique vidéo,Online SupportCapacity:72000 Capsules/hourCondition:NewAutomatic Grade:AutomaticWeight:1100K…

- Livraison estimée : 7 Jours de livraison rapide

- Certification : cGMP CE ISO SGS et etc.

- Service après-vente assuré : Ingénieurs disponibles pour entretenir les machines à l’étranger.

| Description détaillée du produit | |||

|---|---|---|---|

| Nom: | NJP 1200 High Speed Automatic Capsule Filler Equipment Pharmacy Machines | ||

| Service après-vente fourni: | Ingénieurs disponibles pour entretenir les machines à l’étranger,Support technique vidéo,Assistance en ligne | ||

| Capacité: | 72000 Capsules/hour | ||

| Condition: | New | ||

| Automatic Grade: | Automatic | ||

| Poids: | 1100KG | ||

| Type: | Filling Machine | ||

| Dimension(l*w*h): | 900*870*1950mm | ||

| Tension: | 220V/380V 50Hz | ||

| Pouvoir: | 5.5kw | ||

| Driven Type: | Electric | ||

| Garantie: | 12 Months | ||

| Souligner: |

remplisseuse de capsules automatique, pill filler machine |

||

NJP 1200 High Speed Automatic Capsule Filler Equipment Pharmacy Machines

| Description détaillée du produit | |||

|---|---|---|---|

| Capacité de production | 72000 pièces/h | ||

| Poids net de la machine | 1100Kilogrammes | ||

| Taille globale de la machine | 900×870×1950 | ||

| Pouvoir | 380/220V 50 Hz | ||

| Puissance totale | 5.5KW | ||

| Nombre d'alésages de segment | 9 | ||

| Vide | 40m3/heure-0.04-0.08Mpa | ||

| Collecteur de poussière | 24.5Kpa 210m3/h | ||

| Bruit | <75Base de données(UN) | ||

| Taux de réalisation | Capsule vide 99.9% Capsule complète 99.8% | ||

| Capsule applicable | 00,0,1,2,3,4,5# | ||

| Erreur de remplissage | Médecine occidentale:±3% Médecine chinoise:±4% | ||

| Produit applicable | Pouvoir,granule,pastille,comprimé | ||

| Poids | 1100Kilogrammes | ||

| Packing size | 1490×1260×2150mm | ||

1.This automatic capsule fill machines can automatically finish the production process including sowing, capsule separating, filling, locking, unqualified capsule rejected and finished products output.

2.The capsule filling machine has the advantages of accurate loading, stable operation and no dust.

3.Rotary of capsule filling machine design to obtain a patent for utility model, the sealing ring using imported SIL silicone rubber, effectively prevent powder into the internal turntable, good sealing performance, no dust overflow pollution

4.Transverse biaxial adapt PTFE oil-less bearing, no need refueling; structure modulaire, equipped with jog operation, convenient maintenance and cleaning, replacement of mold only 15 minutes,our capsule filling machine is newest.

5.Guangdong Rich Packing Machinery Co., Ltd. est un fabricant et fournisseur professionnel de machines et d'équipements pharmaceutiques et d'emballage en Chine.

Features:

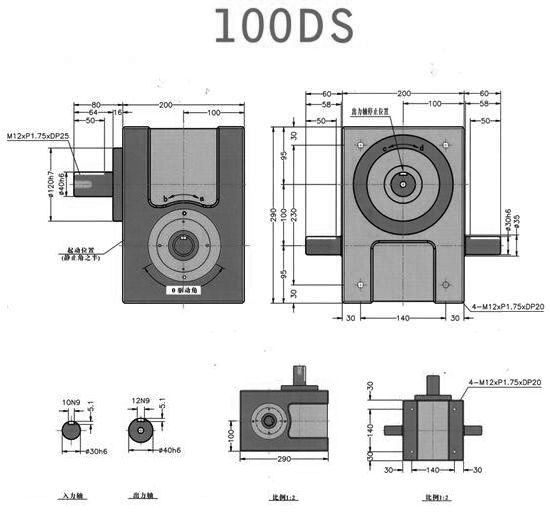

100DS Cam: The diameter of force input shaft is 30CM , the diameter of force output shaft is 40CM.

The utility model has the advantages of good stability, button and torque of the large and long service life, completely changed the previous 83DS frequent failure, even into the power output shaft axis and fault phenomenon.

6.This pharmaceutical capsule filling machine has safety firs, all the working stations take full account of the personal safety, such as the door control and emergency stop switch.

7.Guangdong Rich Packing Machinery Co.. Ltd.'s capsule filler machine deploy segmentation adapt German Cai Si for 3 secondes (Zeiss) indexation de la tête de division optique, l'arbre d'indexation a effectué un traitement unique, chargement et haute précision,

l'erreur est inférieure ou égale à 3%.

8.The capsule filler machinery is precision mold concentricity, zero deviation, ensure that the capsule is not wiping, no damage.

9. Automatic rejection device, improve the charging efficiency ,the capsule filling equipment is suitable to pharmacy and health care food manufacture.

10.One-year warranty period for whole machine except of tubes and human factors etc, and 12-month of after-sale service from the date when you receive machine or 12 months when installation finished